Biscuit Making & Baking Machines |

Biscuit Baking Oven

Construction:

Ask for Price?

The

biscuit baking oven body consists of steel steamtight tunnel with equally

divided zones of the radiators. Stainless steel expansion joints are

provided between these zones in order to eliminate the expansion of the oven

section. The inspection doors are provided for inspection of the baking

goods during the process.

Firing Chambers:

The complete chamber of biscuit making oven will be insulated with

minerwoll filled from outside to conserve heat and increase efficiency. The

fully automatic imported burner shall be fitted to the chamber and the

temperature shall be controlled by automatic temperature controller on the

control panel.

Insulation:

The complete biscuit making oven will be covered with 10" thick

mineral wool insulation from top, bottom and the sides. The bottom portion

of the oven at the sides will be covered with CRC sheets for the conveyor

protection and to avoid heat loss.

Baking System:

Ask for Price?

The

baking in the heating chamber of biscuit baking oven takes place by

radiators located under and above the wire mesh band which distribute heat

for uniform baking. The recirculation heating gases of these radiators can

be controlled for each zone separately. The closed recirculation system is

having slight vacuum so that combustion gases can not enter into the baking

chamber. The ventilating fan is for circulation of the heating gases through

the recirculation system and thermostatically controlled burners provide the

set temperature of the heating gases.

Fans:

All the circulating fans are fabricated from M.S. & S.S. and will be

well balanced to avoid vibration and will give noise free operation in high

speeds.

Application:

Ask for Price?

This machine is fitted with 7" Coloured T.F.T touch screen which means lot of space (Lot of recipe Capacity)in short now production of cookies is on your finger tips.Available in 4 to 12 nozzles suitable 10" to 32 "tray with L the tray as per customers choice.

Features of this machine are:

» Nozzle rotation is powered by a multi speed geared motor

» Up and Down movement of the table is powered by a servo geared motor

» Table height adjustment is fully automatic

» Wire cut frame is powered by a servo geared motor

» Multi layered & conical shaped cookies

» Hole in centre of cookies for depositing filling jam etc

» Servo drive controls for high speed and accuracy

» This machine operates on independent motors for all the functions ,which give you the flexibility of making different kind of products

Good Positioning control:

THE tray movement powered by a servo motor ,which result in adequate positioning control.

| No. of Cookies per Row | Tray width Required | Max.ProductionCapacity Per Hour | Weight of Machine | Dimension ofMachine in mm (LxWxH ) | Power Load KW |

| 4 | 10”/250mm | 40-50kg | 525kg | 780x1040x1550 | 2 |

| 5 | 12”/300mm | 50-60kg | 550kg | 780x1040x1550 | 2 |

| 6 | 16”/400mm | 140-150kg | 675kg | 800x1040x1650 | 2.5 |

| 7 | 18”/450mm | 165-175kg | 700kg | 800x1050x1650 | 2.5 |

| 8 | 20”/500mm | 190-200kg | 700kg | 800x1050x1650 | 3 |

| 9 | 24”/600mm | 215-250kg | 825kg | 800x1200x1650 | 3.5 |

| 10 | 27”/680mm | 240-250kg | 825kg | 800x1200x1650 | 3.5 |

| 12 | 32”/800mm | 340-350kg | 1200kg | 800x1450x1650 | 4.5 |

Application:

Ask for Price?

Laminators

are biscuit making machines, generally used for all kinds of hard biscuit

making, crackers making and cocktail snacks making. With laminator it is

possible to create a puffy pastry-like structure, which is of decisive

importance for the quality level and consequently for the sales success.

Laminating of Dough band improves the weight/volume ratio considerably i.e.,

quantity increase at same weight.

Operation:

In this superior functioning biscuit making machine the dough band received

from sheeter of 838mm width is passed through two shuttles. The dough sheet

is cut into pieces by a knife for a length of 1000mm (39") and these

pieces are laid on bottom shuttle by top shuttle. This bottom shuttle layers

the pieces on first conveyor unit of 1000mm (39") wide production line

very carefully. The first conveyor unit feeds to the first gauge roll unit.

Number of layers can be controlled by the speed of first conveyor unit or

increasing the speed of sheeting unit and laminator by AC variable frequency

drive.

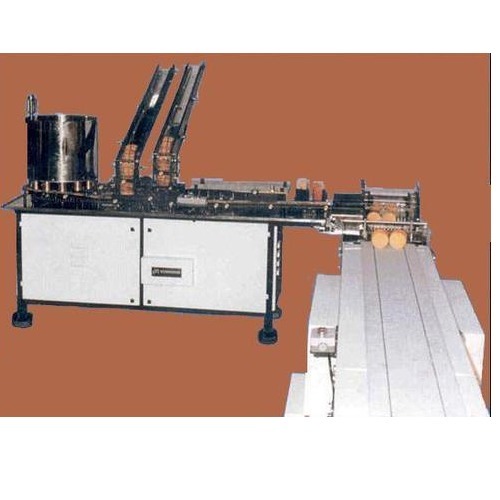

Cooling Conveyor and Stacker Machine

Ask for Price?

Construction:

Cooling conveyor is made in a modular construction of 2.5 Mtrs. long and

connected together to form the required length. The supporting side channels

are fabricated from 3mm thick M.S. sheet.

Idle rollers are spaced at 750mm apart on conveying direction and 1700mm on

the return direction. All the idle rollers are of 48mm dia, mounted on 6004

ZZ deep groove ball bearings with grinding finish and hard chrome plated for

hygienic conditions.

As you know very well practically about the droppings of oil from the cloth

due to rubbing of cloth against tie angles when producing high fat biscuits.

To minimise this we replaced the all tie angles also with idle rollers. This

might costs little extra, but you can maintain hygienic conditions at

working area.

Drive drums are two no's. of 220mm dia and projections are made on the

surface of drums to minimise slip or covered with friction grip rubber tape.

Manual tensioning and tracking are provided.

You can rely only on feeder table to stack the oil sprayed biscuits which

does not require more travel after oil spraying.

The biscuit coming from stripping conveyor is directed on to the cooling

conveyor to transfer the heat in the biscuit to atmospheric air as it is

passing on it. The recommended total travel of the cooling conveyor is 1.5

times the oven length. As per your specifications you need the travel of 150

ft. for effecting cooling.

Oil Sprayer

Ask for Price?

The Oil Spray

Machine is used to spray fine most of edible oil on the top and bottom of

hot biscuits coming out of oven before being transferred to cooling

conveyor.

Cream Biscuit Sandwiching Machine

Ask for Price?

We

manufacture and export wire cut type cream biscuit sandwiching machine,

which is designed to produce a wide range of biscuit sandwiches in

various shapes and sizes. Cream deposit can be uniformly thick or

thin... large or small.... square or rectangular... as required to match

base biscuit size and shape.

Features:

- Automatic self contained unit.

- All stainless steel contact parts.

- 2 models to suit biscuit size.

- Ease of change over to different varieties of biscuit in minimum

time.

- Sandwiches are stacked on edge in rows on take-off conveyor for

easy packaging.

- Simple to operate and easy to maintain.

- Compact, mobile and easy to clean.

- Finer engineering

- Superior construction

- More functional design

- More efficient operation

|

|

Specifications:

| Sr. No. |

DESCRIPTION |

MODEL - ME 10 |

MODEL ME 8 |

| 1. |

Number of Nozzles |

10 |

8 |

| 2. |

Biscuit size - Round |

28-50 Dia |

55-80 Dia |

| Biscuit size - Square |

30-45 |

55-75 |

| Biscuit size - Rectangular (Minimum) |

25 X 65 |

50 X 80 |

| Biscuit size - Rectangular (Maximum) |

40 X 65 |

65 X 80 |

| 3. |

Stacking on Edge |

3 rows |

2 rows |

| 4. |

Output per minute (approx) |

600 sandwiches |

400 sandwiches |

| 5. |

Cream deposition |

0-6 grams |

5-15 grams |

| 6. |

Power required (440V - 3 phase) -

for sandwiching machine |

2 H. P. |

2 H. P. |

| - for conveyor |

0.5 H. P. |

0.5 H. P. |

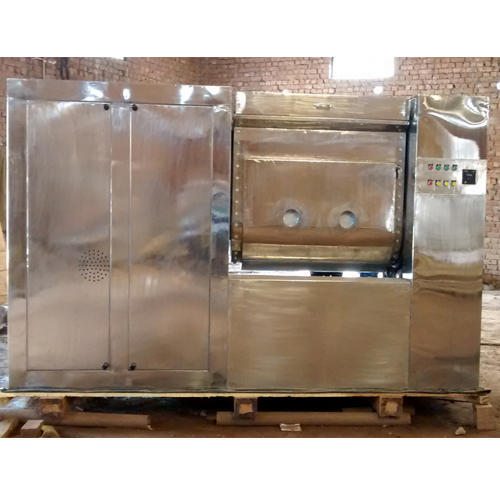

Horizontal Dough Mixer

Ask for Price?

Application :

The dough mixer is used for mixing various ingredients such as flour, sugar, fat, water, and other chemicals for making hard, soft or fermented dough for making biscuits.

Design :

A base plate over which two side frames are fitted for taking the load of mixing chamber of bread dough mixer which is fitted on side frames. In the mixing chamber of bread dough mixer two Z/sigma type-mixing blades are fitted which rotate at different speeds in opposite direction to mix various types of soft/hard dough for achieving required glutton of dough. An electrically operated tilting device is also fitted to tilt mixing chamber to unload mixed dough. The machine is covered from all sides to avoid dust and accidents etc.

Contact parts :

In the standard model, all contact parts are made of mile sheet/ cast iron but the top lid in S.S.-304. However, all contact parts can be supplied in S.S.-304.

Leakage protection :

The mixing bowl is protected by double oil seals with gland rope in all four shafts of blades to avoid leakage of liquids from the mixing chamber.

Power load :

10HP & 1 HP, 20HP & 2HP, 30 HP & 3 HP respectively.