Biscuit Making & Baking Machines |

Dough Mixer

Ask for Price?

Application:

The dough mixer is used for mixing various ingredients such as flour,

sugar, fat, water, and other chemicals for making hard, soft or fermented

dough for making biscuits.

Design:

A base plate over which two side frames are fitted for taking the load of

mixing chamber of bread dough mixer which is fitted on side frames. In the

mixing chamber of bread dough mixer two Z/sigma type-mixing blades are

fitted which rotate at different speeds in opposite direction to mix various

types of soft/hard dough for achieving required glutton of dough. An

electrically operated tilting device is also fitted to tilt mixing chamber

to unload mixed dough. The machine is covered from all sides to avoid dust

and accidents etc.

Capacity:

100 Kg. Flour, 200 Kg. Flour, 300 Kg. Flour per batch.

Contact parts:

In standard model all contact parts are made in mile sheet/ cast iron but

the top lid in S.S.-304. However all contact parts can be supplied in

S.S.-304.

Leakage protection:

The mixing bowl is protected by double oil seals with gland rope in all

four shafts of blades to avoid leakage of liquids from the mixing chamber.

Power load:

10HP & 1 HP, 20HP & 2HP, 30 HP & 3 HP respectively.

Rotary Moulder (Soft Dough making

Machine)

Ask for Price?

Rotary Moulder is an alluring chattel aimed to extrude your search for a quality net of its type.

Applications :

Rotary Moulder is used for the desired shape out of soft dough & soft variety of biscuits like glucose.

Design :

The dough to be moulded Is fed into the hopper & a forcing roller force the dough into the cavities off the moulding roller made out of gum metal ,uniformly engraved & & coated with food grade Teflon.

Excess dough is cleared with a knife ,which is held by a holder made tool steel .to ensure uniform filling.

Rotary Cutter (Hardouh Cutter)

Application:

Ask for Price?

The

single head rotary cutter prints fine design on a continuously fed dough

sheet and also cuts out the individual dough piece. It is used for pre

baking forming for marie , thin arrowroot, krackjack, petit-beure, monaco,

and all types of salty biscuits.

Operation

The unit powered by 1.5KW helical geared motor and speed controlled by AC

frequency controller. Drive is given to cutting roller only to accommodate

different sizes of die's in this machine.

Rubber lined anvil roller is adjustable in height so that pressure can be

controlled at both sides in parallel or independently. The anvil roll is

being driven by friction of the cutting web, which is independently powered

by its own separate drive. For safety reasons the cutting roll is provided

with guard, removal of which stops the motor.

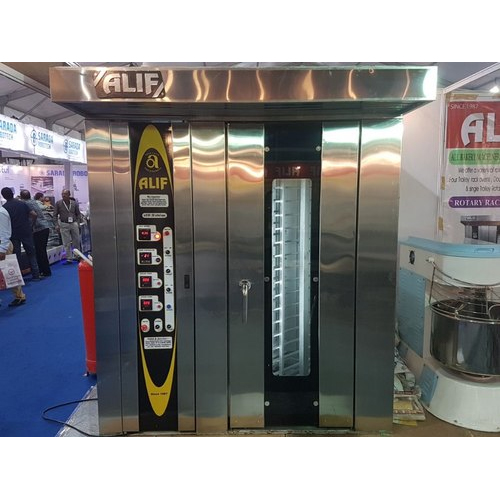

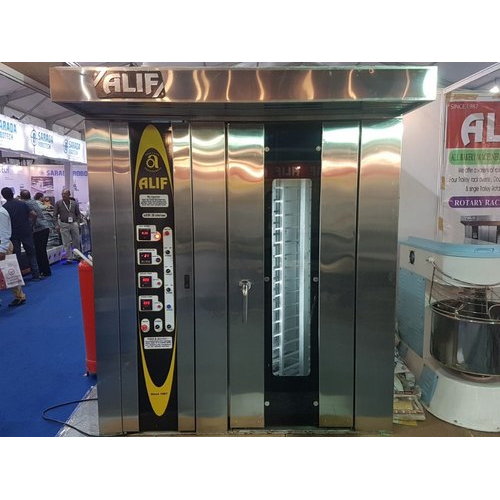

Stainless Steel Baking Oven

Application:

Ask for Price?

» Rotary rack oven with rotating rack and large.Extended stainless steel steel hood.

» Maintenance only from front and top

» Rapid heat-up to baking temperature at start of production. Room temperature to 225*in 20minutes.

» Ideall to bake all varities of bakery products. Such as breads, baguettes, rusk, pastries, cakes, biscuits, khari, aflatoon, nankhatai etc.

» Stainless steel baking chamber with imported burner.

» Even and excellent baking with equally heat distribution.

» Full view of baking products from window of one piece.

» Stainless steel ddor provided with toughened glasses.

» Simplified manually and automatic contel panel in two languages with symbol for easy baking and steaming.

» Ideal for use in bakeries,hotels,restaurants,schools,supermarket etc

» Heating source will be diesel, LPG, Electric & Wooden fire

» Full stainless steel and steam sysytem on option

» 3 Phase 440V or single Phase 220V

» Roatry rack oven can be delivered fuuly asssembled o disassembled .So that it fits via a smaller door

Fully Automatic Wire Cut Cookies Machine

Application:

Ask for Price?

This machine id fitted with 7" coloured T.F.T touch screen which means alot of space (LOT OF RECIPE STORAGE CAPACITY)in short now production of cookies is on your finger tips .Available in 4 to 12 Nozzles suitsble 10" to 32" tray with L the tray as per customers choice

Features of this machines are

» Nozzle rotation is powered by a multi speed geared motor.

» Up and down movement of the table is powewred by a servo geared motor.

» Table height adjustment is fully automatic is fully autoamtic

» Wire cut frame is powered by a servo geared motor.

» Multi layered & conical shaped cookies.

» Hole in center of cookies for deposting filling jam etc.

» Servo drive controls for high speed and accuracy.

» This machine operates on independent motors for all the functions, which give you the flexibility of making different kind of products

| No. of Cookies per Row | Tray width Required | Max.Production Capacity Per Hour | Weight of Machine | Dimension ofMachine in mm (LxWxH ) | Power Load KW |

| 4 | 10"/250mm | 40-50kg | 525kg | 780x1040x1550 | 2 |

| 5 | 12"/300mm | 50-60kg | 550kg | 780x1040x1550 | 2 |

| 6 | 16"/400mm | 140-150kg | 675kg | 800x1040x1650 | 2.5 |

| 7 | 18"/450mm | 165-175kg | 700kg | 800x1050x1650 | 2.5 |

| 8 | 20"/500mm | 190-200kg | 700kg | 800x1050x1650 | 3 |

| 9 | 24"/600mm | 215-250kg | 825kg | 800x1200x1650 | 3.5 |

| 10 | 27"/680mm | 240-250kg | 825kg | 800x1200x1650 | 3.5 |

| 12 | 32"/800mm | 340-350kg | 1200kg | 800x1450x1650 | 4.5 |

Semi Automatic Wire Cut Cookies Machine

Application:

Ask for Price?

This machine is fitted with 7" Coloured T.F.T touch screen which means lot of space (Lot of recipe Capacity)in short now production of cookies is on your finger tips. Available in 4 to 12 nozzles suitable 10" to 32 "tray with L the tray as per customers choice.

Features of this machines are

» Nozzle rotation is powered by a multi speed geared motor

» Up and Down movement of the table is powered by a servo geared motor

» Table height adjustment is fully automatic

» Wire cut frame is powered by a servo geared motor

» Multi layered & conical shaped cookies

» Hole in centre of cookies for depositing filling jam etc

» Servo drive controls for high speed and accuracy

» This machine operates on independent motors for all the functions ,which give you the flexibility of making different kind of products.

| No. of Cookies per Row | Tray width Required | Max.ProductionCapacity Per Hour | Weight of Machine | Dimension ofMachine in mm (LxWxH ) | Power Load KW |

| 4 | 10"/250mm | 40-50kg | 525kg | 780x1040x1550 | 2 |

| 5 | 12"/300mm | 50-60kg | 550kg | 780x1040x1550 | 2 |

| 6 | 16"/400mm | 140-150kg | 675kg | 800x1040x1650 | 2.5 |

| 7 | 18"/450mm | 165-175kg | 700kg | 800x1050x1650 | 2.5 |

| 8 | 20"/500mm | 190-200kg | 700kg | 800x1050x1650 | 3 |

| 9 | 24"/600mm | 215-250kg | 825kg | 800x1200x1650 | 3.5 |

| 10 | 27"/680mm | 240-250kg | 825kg | 800x1200x1650 | 3.5 |

| 12 | 32"/800mm | 340-350kg | 1200kg | 800x1450x1650 | 4.5 |

Bread Baking Traveling Oven

Application:

Ask for Price?

» Rotary rack oven with rotating rack and large.Extended stainless steel steel hood.

» Maintenance only from front and top

» Rapid heat-up to baking temperature at start of production. Room temperature to 225*in 20 minutes.

» Ideall to bake all varities of bakery products. Such as breads, baguettes, rusk, pastries, cakes, biscuits, khari, aflatoon,nankhatai etc

» Stainless steel baking chamber with imported burner.

» Even and excellent baking with equally heat distribution.

» Full view of baking products from window of one piece.

» Stainless steel ddor provided with toughened glasses.

» Simplified manually and automatic contel panel in two languages with symbol for easy baking and steaming.

» Ideal for use in bakeries,hotels,restaurants,schools, supermarket etc

» Heating source will be diesel,LPG,Electric & Wooden fire

» Full stainless steel and steam sysytem on option

» 3 Phase 440V or single Phase 220V

» Roatry rack oven can be delivered fuuly asssembled o disassembled .So that it fits via a smaller door